It's not manufacture. It's Art!

Sanco is a state-of-the-art production facility where craftsmanship and technology coexist in harmony.

Equipped with high-precision machinery, automated lines, and dedicated stations for handmade work, we handle everything in-house — from raw material selection to packaging and delivery.

Whether producing custom components or entire handcrafted collections, our expert team brings together engineering mastery with artistic finesse.

Sanco proudly chooses to invest and manufacture in Europe, believing in the value of proximity, quality, and responsibility.

In an era of outsourcing, we remain true to our roots —

we create where we live!

17,000 m² of creativity. 100% in-house.

Our production takes place in a fully integrated factory of 12,000 m², within a privately-owned industrial site of 17,000 m² in Athens.

Every Sanco product is born, designed, manufactured, and finished under one roof.

No outsourcing. No compromises. Just complete control — from raw brass to the final touch.

We are one of the few bathroom accessory brands in the world that produce 100% in-house.

Brass casting at its finest — powered by Swiss precision.

We cast our brass components in-house at temperatures exceeding 950°C, using high-pressure die casting.

Each mold is custom-engineered to define the final shape — with accuracy, repeatability, and strength.

To elevate casting quality, we’ve integrated a Fondarex vacuum system, developed in Switzerland and casting by INDRA Italian press.

This technology removes trapped air before solidification, ensuring:

– Perfect compaction

– Zero porosity

– Flawless surface finish

This is not just casting. It’s precision metallurgy, forged in heat and sealed in vacuum.

_800.jpg)

PVD transforms pure metals into extraordinary finishes!

In a vacuum-sealed environment, under temperatures up to 600°C,

metals like titanium, zirconium, and chromium are turned into ionized vapor — a radiant plasma.

This plasma fuses with gases like nitrogen, argon, acetylene, and oxygen, creating molecular coatings of exceptional beauty and resistance.

What emerges is not just color — but a new skin of the metal, richer, deeper, and nearly indestructible.

With more than 30 curated finishes, our PVD process redefines luxury in the bathroom.It’s not surface treatment. It’s elemental transformation.

“Crafted by robots. Perfected by people.”

The pursuit of perfection starts with consistency — and that’s where our robotic polishing units excel.

They deliver millimetric precision, repeatability, and flawless satin or mirror effects across large volumes.

But true beauty lies in the details.

That’s why every piece still passes through our master finishers, who bring out the final glow with hand-polishing techniques honed over decades.

Whether it’s satin, mirror, or brushed, the result is a surface that feels alive, not just finished.

Technology gives us control. Craftsmanship gives us soul.

SANCO LAB!

“We design from scratch. We manufacture from scratch.”

At the heart of Sanco lies our dedicated engineering & innovation lab.

Here, our team of top-level mechanical engineers designs, tests, and refines every detail — from the internal structure to the outer form.

Every new product begins as an idea.

We sketch it, simulate it, prototype it in 3D, and test it for strength, functionality, and longevity.

With full control over the process, we don’t just design to impress —

we design to endure.

Whether we’re developing a complex component or pushing the boundaries of finishing techniques,

Sanco Lab is where art meets engineering.

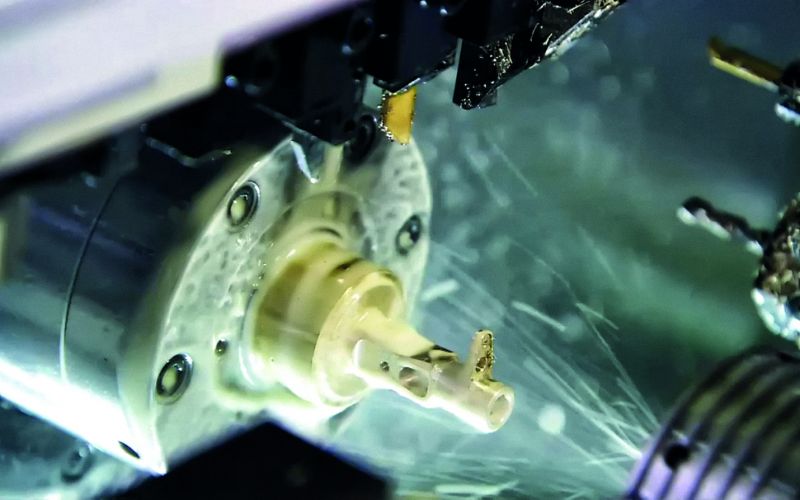

From turning to spinning — total control in geometry.

Our CNC sector combines high-speed lathes, multi-station transfer systems, and spinning CNC technology to shape components with extreme accuracy and repeatability.

Each step — from simple turning to complex rotational forming — is handled in-house, allowing us to define geometry down to the micron.

These systems ensure consistency across collections, reduce human error, and unlock advanced forms that manual tooling could never achieve.

It’s industrial sculpture.